Central China's Tianmen weaves digital success in garment?industry

Hostess Yingzi sells clothing via livestreaming at Tianmen Qianguang Media's studios on June 29, 2025. (People's Daily Online/Zhong Wenxing)

Sixty seconds from fabric to finished garment, 500 express packages dispatched per minute, 24-hour non-stop livestreaming, and 3 million clothing items sold daily...

These numbers tell the story: Tianmen, a county-level city in China's Hubei Province, emerges as an e-commerce fashion hub.

Speed defines success

Photo taken on June 25, 2025, shows fabrics and accessories at Changwan Community, Houkou district, Tianmen, central China's Hubei Province. (People's Daily Online/Zhang Jun)

"Submit your design in the morning, take your finished garments by afternoon," promises Wu Jiawen, Party secretary of the city's Changwan Community, where over 800 textile businesses have created an industrial ecosystem that moves at lightning speed.

This small community exemplifies Tianmen's industrial velocity. Since 2020, its collective economic income has surged to 530,000 yuan annually, powered by a complete supply chain encompassing everything from fabrics and buttons to printing equipment, logistics, and online marketing platforms.

Supported by logistics upgrades, Tianmen processes over one million packages daily for as little as 1.4 yuan (about 20 cents) per order. In 2024, the area handled 300 million express packages, a 63 percent year-on-year increase.

Photo taken on June 25, 2025, shows a fully automated express sorting center in Tianmen, central China's Hubei Province. (People's Daily Online/Zhong Wenxing)

Integrated ecosystem powers growth

Tianmen has architected a "one core, three towns" development pattern anchored by the China (Tianmen) Garment E-commerce City, Baima Garment E-commerce Base, and Chemical Fiber Textile Industrial Park. This framework supports a complete value chain: Weaving, fabric production, garment manufacturing, e-commerce marketing, and cross-border logistics.

Photo shows the Yongchang New Materials factory in Tianmen, central China's Hubei Province. (People's Daily Online/Zhang Jun)

At the Yongchang New Materials' factory, continuous production lines spin out white nylon filament around the clock. The project, with a total investment of 1 billion yuan, recorded sales of more than 20 million yuan in its first two months of operation. Once running at full capacity, it is expected to generate annual sales of 2 billion yuan. The Tianmen Chemical Fiber and Textile Industrial Park now hosts 15 upstream enterprises, ending decades of dependence on external fabric suppliers.

Mid-tier manufacturers like Laiyitiao and Yuezi Garments have evolved from running basic workshops to sophisticated, large-scale production operations, leveraging returning talent from East China who bring advanced techniques and management expertise.

Inside Tianmen Qianguang Media's studios, livestream hostess Yingzi counts down: "3, 2, 1 - link is live!" Within seconds, 60 dresses are sold. This scene repeats hundreds of times daily across the city's streaming platforms, where 24-hour broadcasts drive massive sales volumes on major e-commerce platforms. Tianmen now holds the top position in Hubei for women's apparel sales on China's major e-commerce platforms.

Digital platform accelerates connections

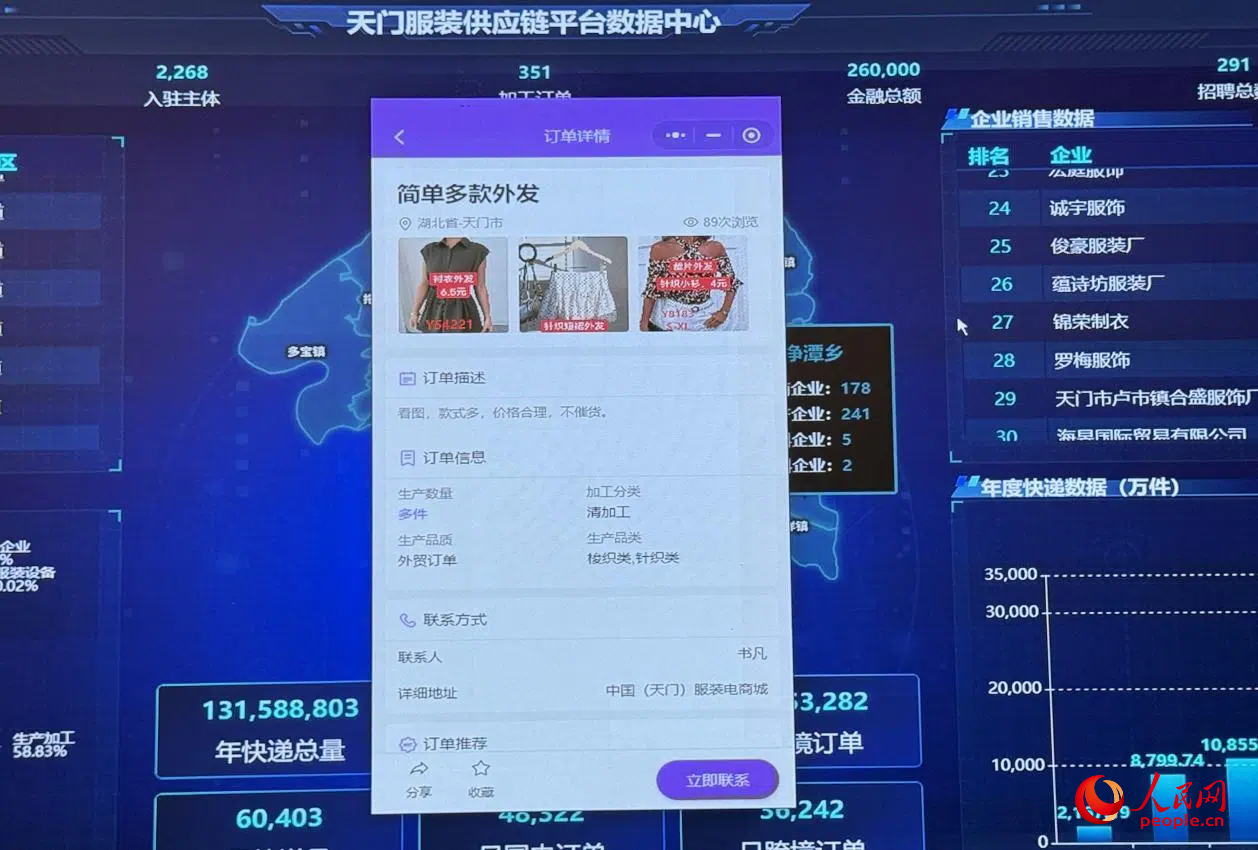

Photo shows Tianmen Yishang Supply Chain Service Platform. (People's Daily Online/Zhang Jun)

Tianmen Yishang Supply Chain Service Platform, backed by a state-owned company and launched in April, epitomizes the digital transformation. With over 20,000 users and 3,000 certified businesses, the platform has facilitated more than 400 supply-demand matches worth over 10 million yuan in mere months.

"Users complete entire supply chain operations through smartphones or computers, from sourcing materials to arranging logistics," explains You Li, the platform's director. "What once took days of phone calls and factory visits now happens in minutes."

From a single nylon thread to cross-border fashion exports, Tianmen has successfully woven traditional manufacturing excellence with digital innovation, creating a model for traditional manufacturing regions.

Photos

Related Stories

- 2nd Chu culture festival kicks off in Jingzhou, China's Hubei

- Feature: Chinese city strikes chord with fine guitar craftsmanship

- Business Trend: Garment boom turns Tianmen?in C China's Hubei?into e-commerce hub

- Turquoise industry thrives in Zhushan county, C China's Hubei

- Guitar making industry blossoms in Songzi City, China's Hubei

- China discovers large shale gas reserves

- Water market opens to public in Xuan'en County, central China's Hubei

- Crayfish make a splash in central Chinese city

- Vine tea industry boosts rural incomes in Laifeng County, China's Hubei

- China's Enshi draws visitors since beginning of summer

Copyright © 2025 People's Daily Online. All Rights Reserved.